Go to OUR PHILOSOPHY

2021 To innovate and improve ourselves: we renew our logo and image to reflect the FSC is making. New company values and a mission.

In 2021 we celebrated 65 years of history and we named our Machining Shop after Antonio De Carolis, to honor the man who was the Manager of this department for over 20 years

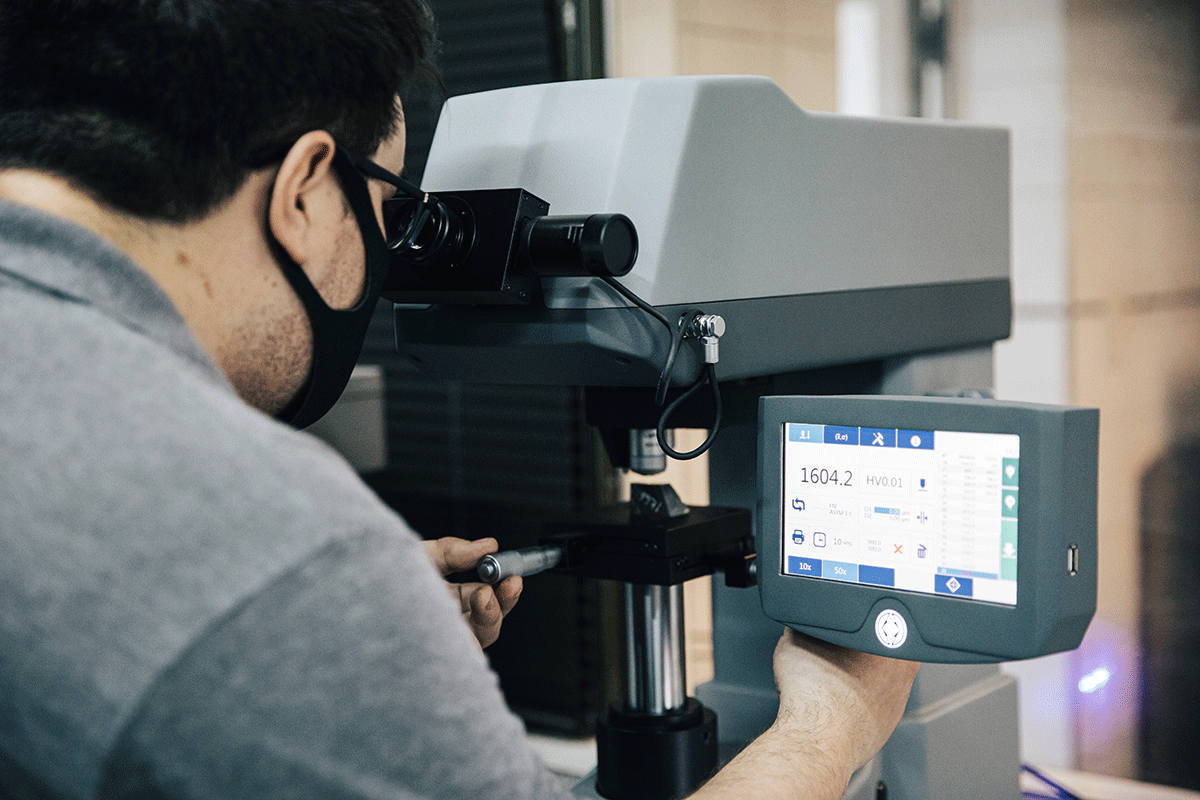

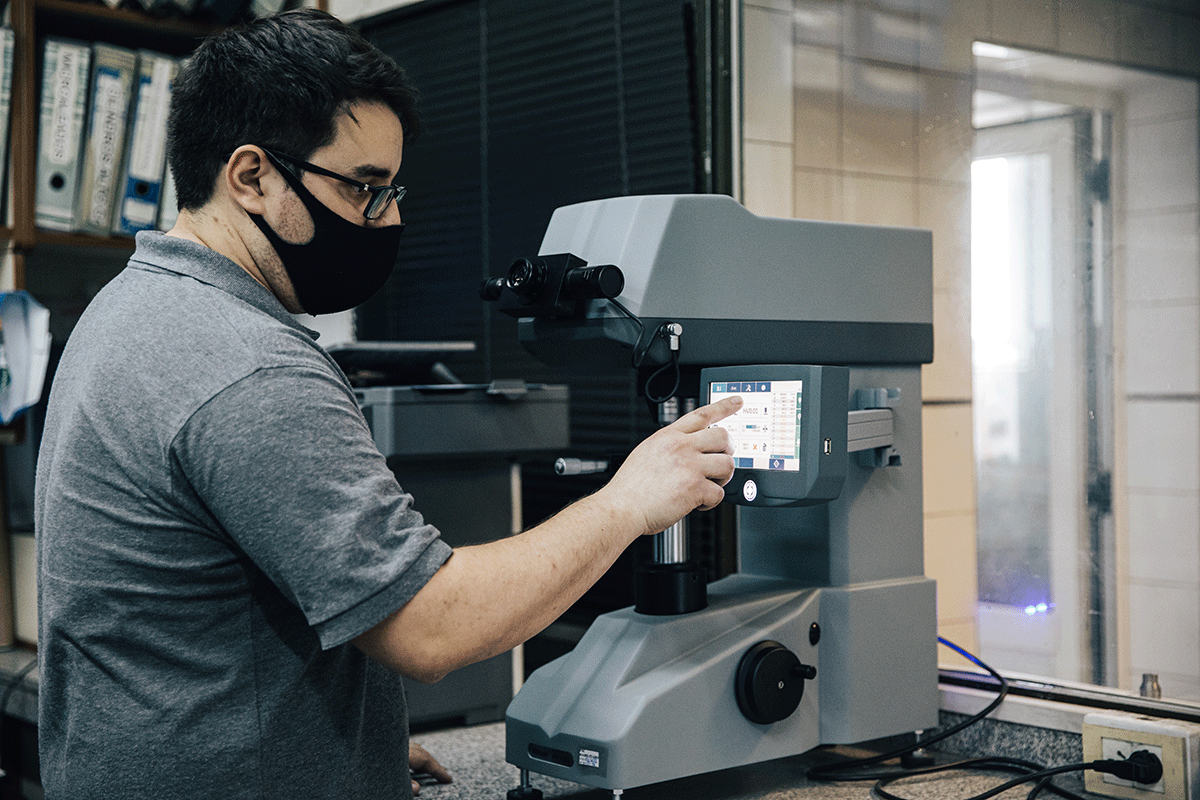

We have incorporated to our R&D labs a new Vickers micro-hardness tester (Wilson VH 1102).

The main purpose of this new tool is to perform hardness measurements in phases and constituents that are present in experimental microstructures.

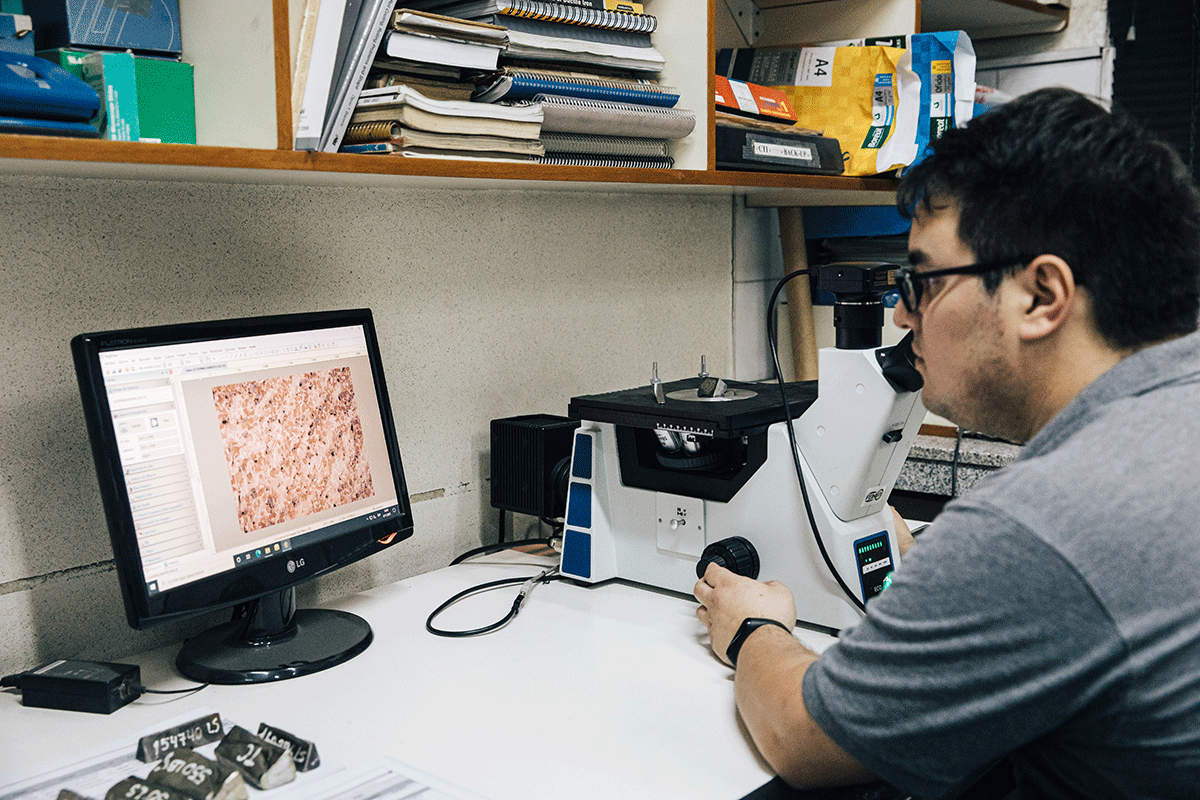

Additionally, a new inverted metallurgical microscope (FEIN Mi50) has been acquired.

This microscope introduces new optical tools like bright field/dark field, polarization, and differential interference contrast (DIC).

These new features increase the lab capabilities for the observation and the characterization of the phases and constituents that are present in the microstructure of those materials we analyze and develop.

In 2020 we achieved the second issue of ON Pyme and we updated the equipment for the development of mining industry materials, such as: improvements in heat treatment furnace, and other measuring equipment.

During 2019 we released the first issue of ON Pyme.

Besides, we increased our involvement in the mining and steel markets and shipped the largest piece in the history of our company and our country: 40 tons of weight casted for one mill roll to our customer Nucor Yamato Steel (USA).

We also manufactured the first vertically centrifugal bimetallic sleeves for Brazil and the USA.

In 2017 we manufactured and developed new horizontal and vertical centrifugal machines. They are used to produce rolls and sleeves for hot strip and universal section mills.

In 2010 we made changes in our organizational structure, and renewed the operational leadership of the foundry, giving an opportunity to a new generation of professionals.

2009 We got certified under the new ISO 9001:2008 norm for all our processes. The audits of environmental approval and declaration of gas emissions were updated.

On top of that, we started our CSR Program, with actions inside our Almirante Brown Industrial Park.

2008 Our first sale of castings for the Wind Industry in our country: Hub, Main Frame, and bearing boxes for NRG Argentina.

2000 – 2007 New induction furnaces were acquired, doubling our melting capacity, and major building reforms were carried out. This allowed us to fully enter the international steel market.

A lathe and a grinder for rolls were developed by us. These projects were designed to insert us as a large manufacturer of hot strip mill rolls. The increases in the production and productivity of the machining shop allowed us to develop new markets in a shorter amount of time.

We received a Certificate of Environmental Suitability

1999 Our process get certified under the ISO-9002/94 Norm

1997 We introduced our liners for the mining industry and rolls for the hot strip mills.

1995 We made our first sell to the United States of America, to Arkansas Steel.

1990 We started to export to other countries in Latin-America, the first countries being Ecuador, Colombia and Brazil

1986 We started the production of mill rolls, a product with higher added value used in the Steel industry.

1984 We surpassed 120 operators and production became of 600 tons per month.

1983 There was a start in the production of of castings and machined parts for the Oil Industry, our main client being Hughes Tool, that afterwards was renamed to Lufkin S.A.

1979 The foundry moved from Temperley to the Almirante Brown Industrial Park with only 10 workers who produced large parts for the Machine Tool Industry.

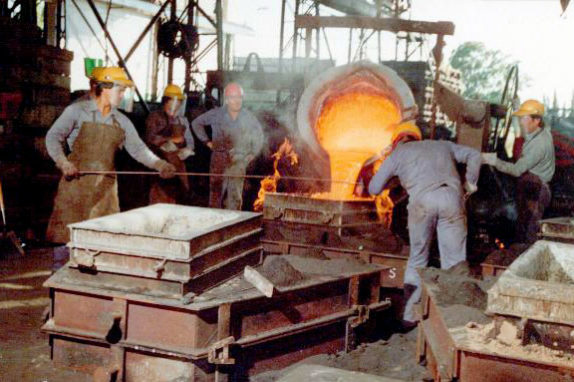

1956 Don Nazareno Sforzini, an Italian foundry man, settles in Argentina and after a period as a foreman, he creates the San Cayetano Foundry in the district of Tres de Febrero, today known as FSC.